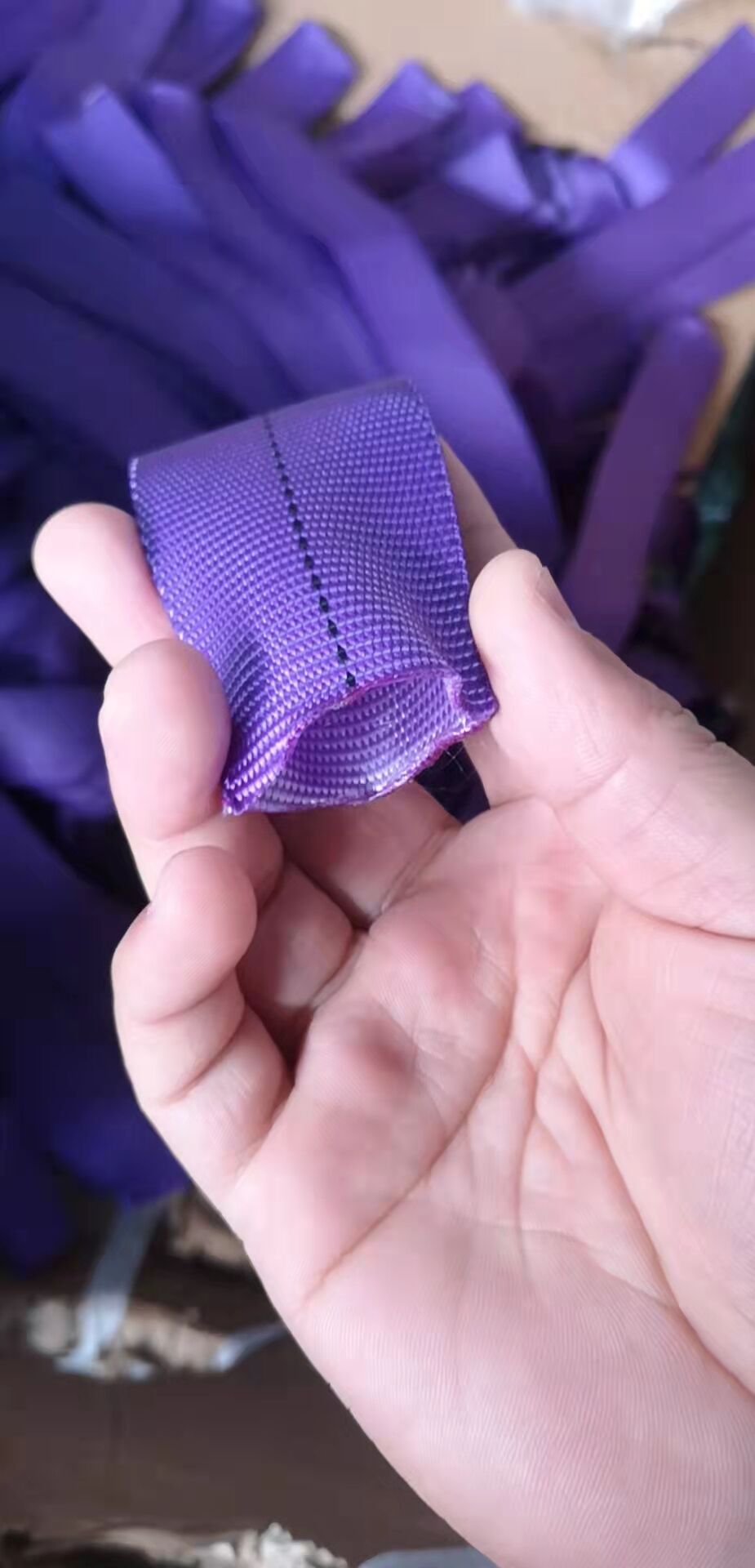

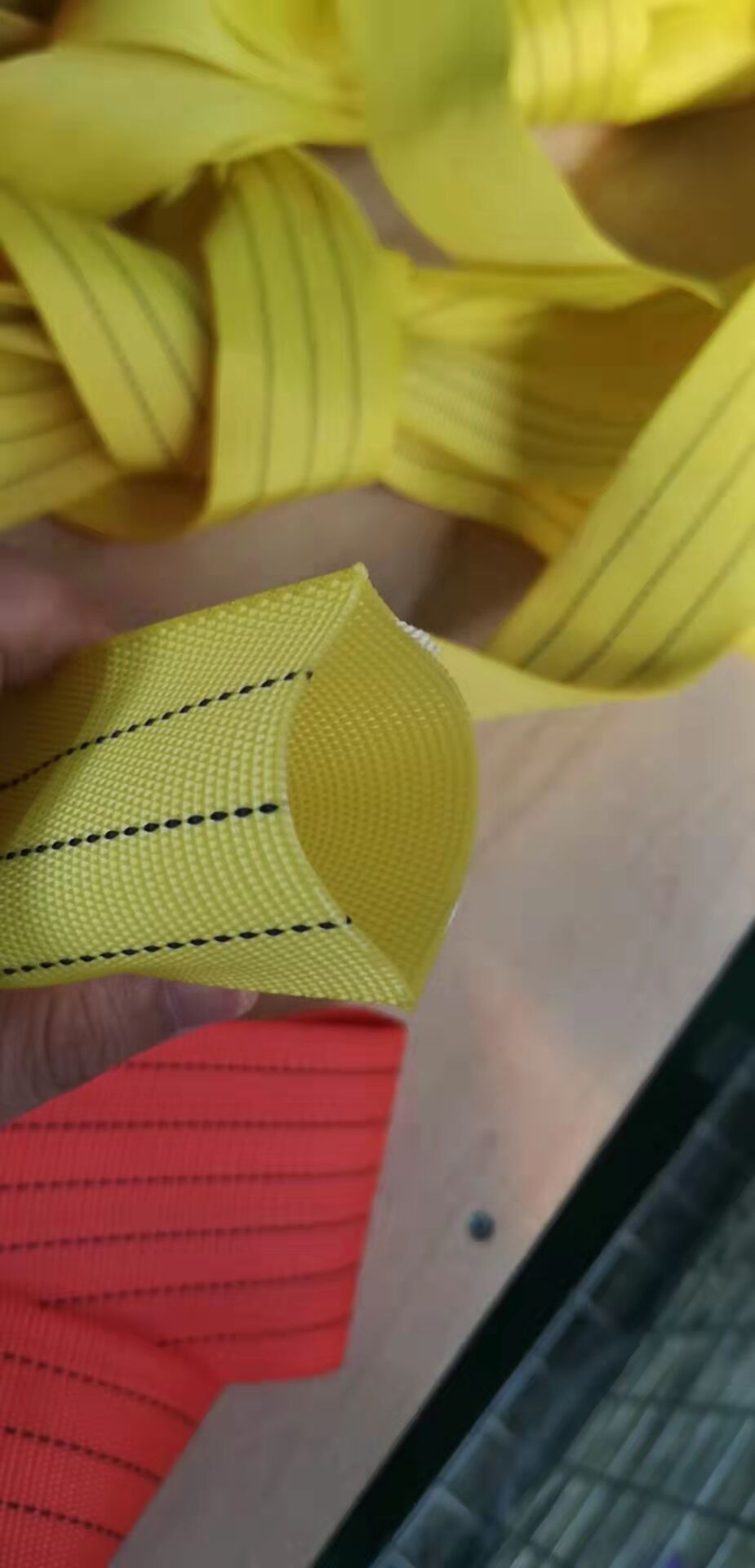

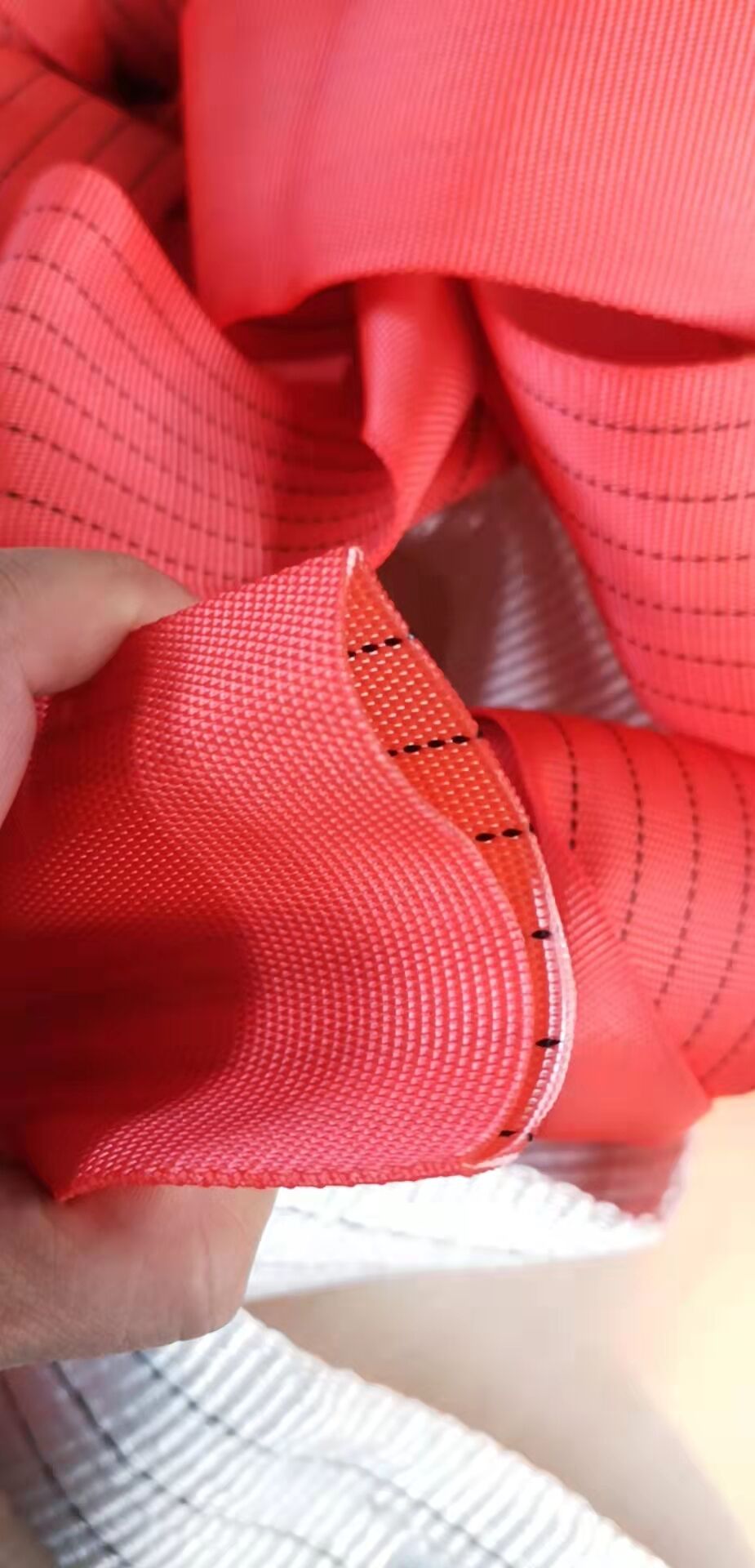

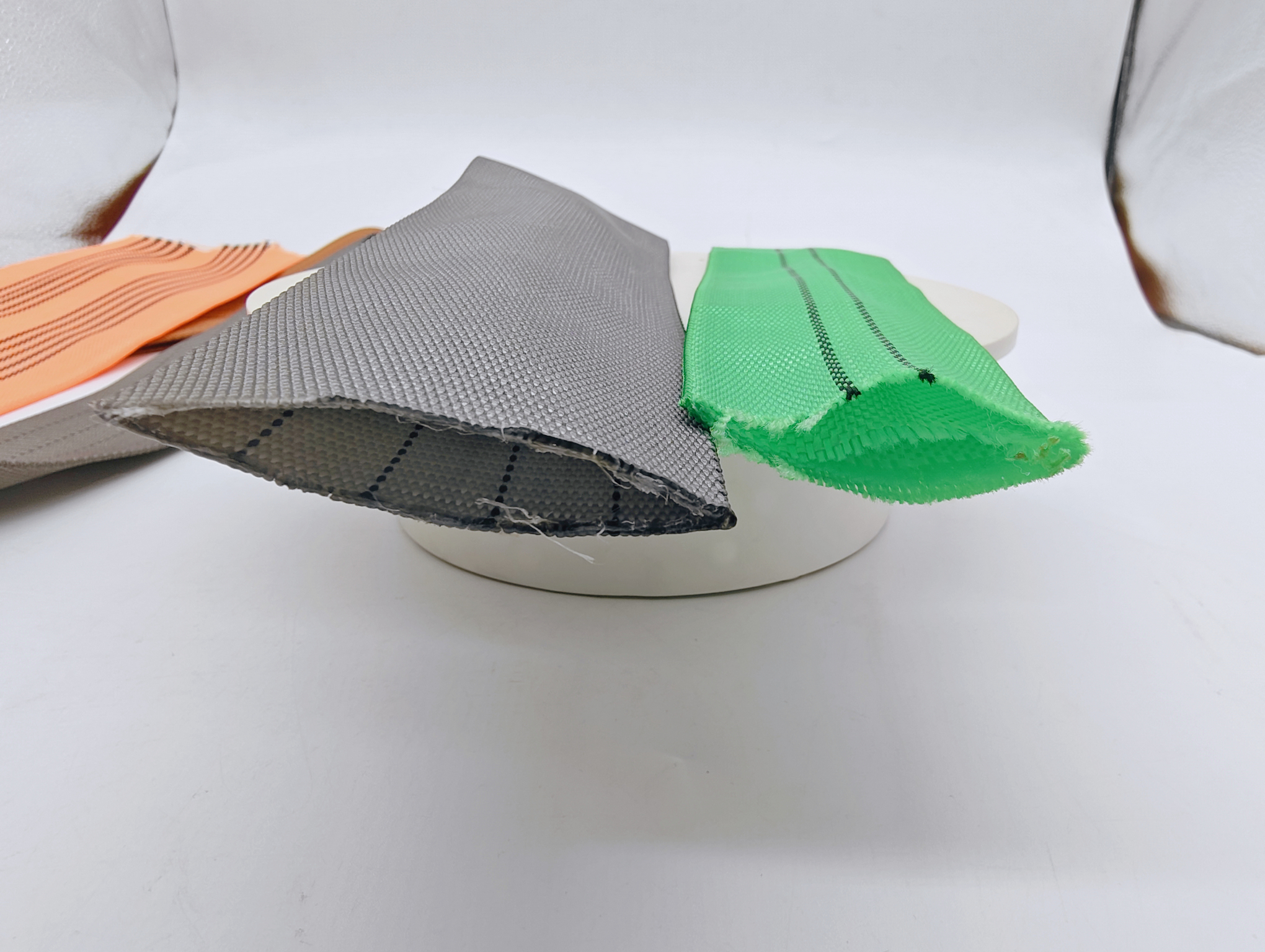

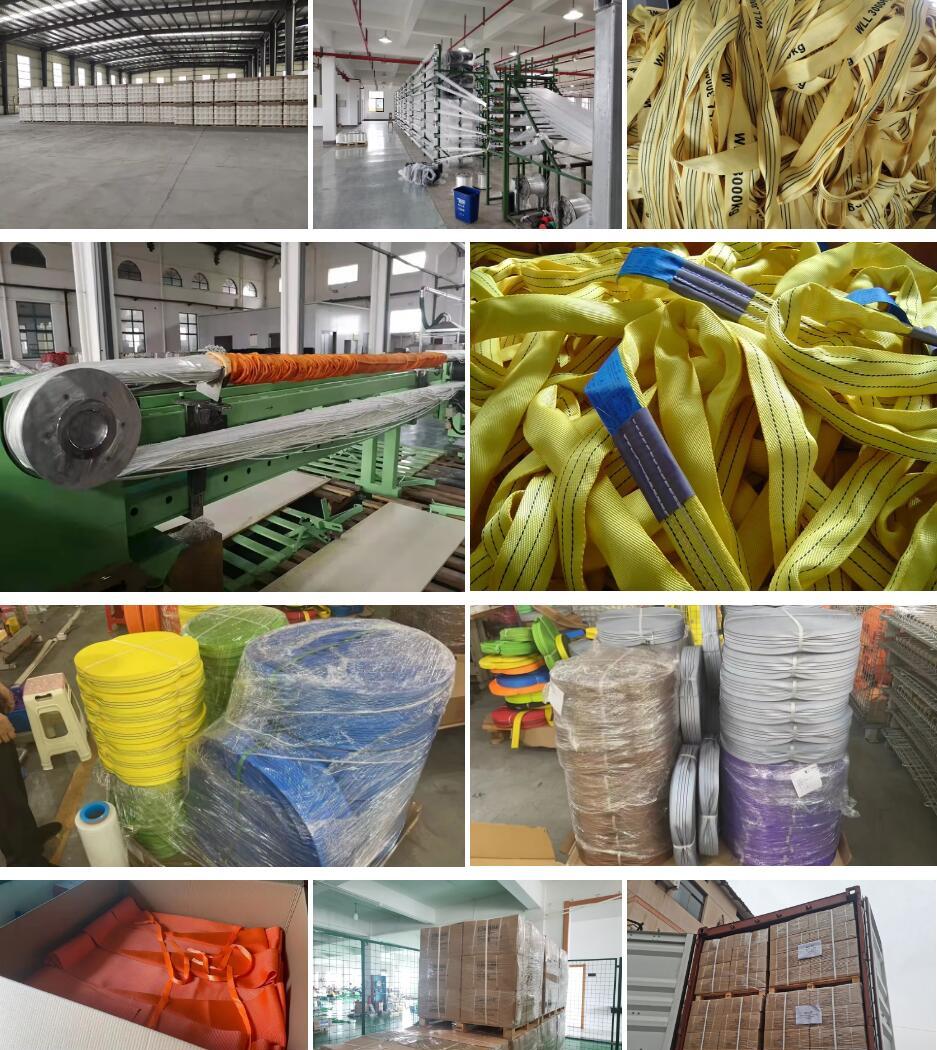

Single / Double Layer Polyester Tubular Round Sling Sleeve

In material handling and lifting industries, safety, efficiency, and equipment longevity are always top priorities. Among the many accessories that support secure lifting practices, the round sling sleeve plays an essential role. Designed to protect both the sling and the load, a round sling sleeve enhances durability, prevents abrasion, and ensures safer lifting operations.

A round sling sleeve is a protective cover, typically made of high-strength polyester, designed to encase a round sling during lifting. It provides a barrier between the sling and sharp edges, rough surfaces, or abrasive contact points on the load. Sleeves are usually tubular in construction and can move freely around the sling, allowing for flexible adjustment during use.

Key Functions

-

Abrasion Protection

Round slings are often exposed to contact with sharp corners or rough surfaces. A sleeve prevents direct wear, extending the working life of the sling. -

Load Protection

In addition to protecting the sling, sleeves prevent damage to delicate or finished surfaces of the load, such as polished steel, wood, or painted equipment. -

Flexibility and Adjustability

Many sleeves are designed to slide along the sling, enabling precise placement where the most protection is needed. -

Safety Assurance

By reducing wear and tear, sleeves help maintain the rated lifting capacity of the sling, minimizing the risk of accidents caused by sling failure.

Types of Round Sling Sleeves

-

Standard Protective Sleeves – Made of polyester or nylon, suitable for general lifting applications.

-

Heavy-Duty Sleeves – Reinforced with additional layers or special fabrics for use with heavy or abrasive loads.

-

Cut-Resistant Sleeves – Constructed with high-performance fibers such as Kevlar® or Dyneema®, designed for environments with sharp edges.

-

Custom Sleeves – Tailored to specific lengths, diameters, or materials to suit unique lifting needs.

Model Number: WDRSS

-

Cautions:

-

Always inspect the sleeve before each use for cuts, wear, or heat damage.

-

Ensure the sleeve fully covers the sling in areas of contact with edges or rough surfaces.

-

Do not rely on sleeves to compensate for improper sling selection or overloading.

-

Use cut-resistant sleeves when handling loads with sharp edges.

-

Store sleeves in a clean, dry environment to maintain material integrity.