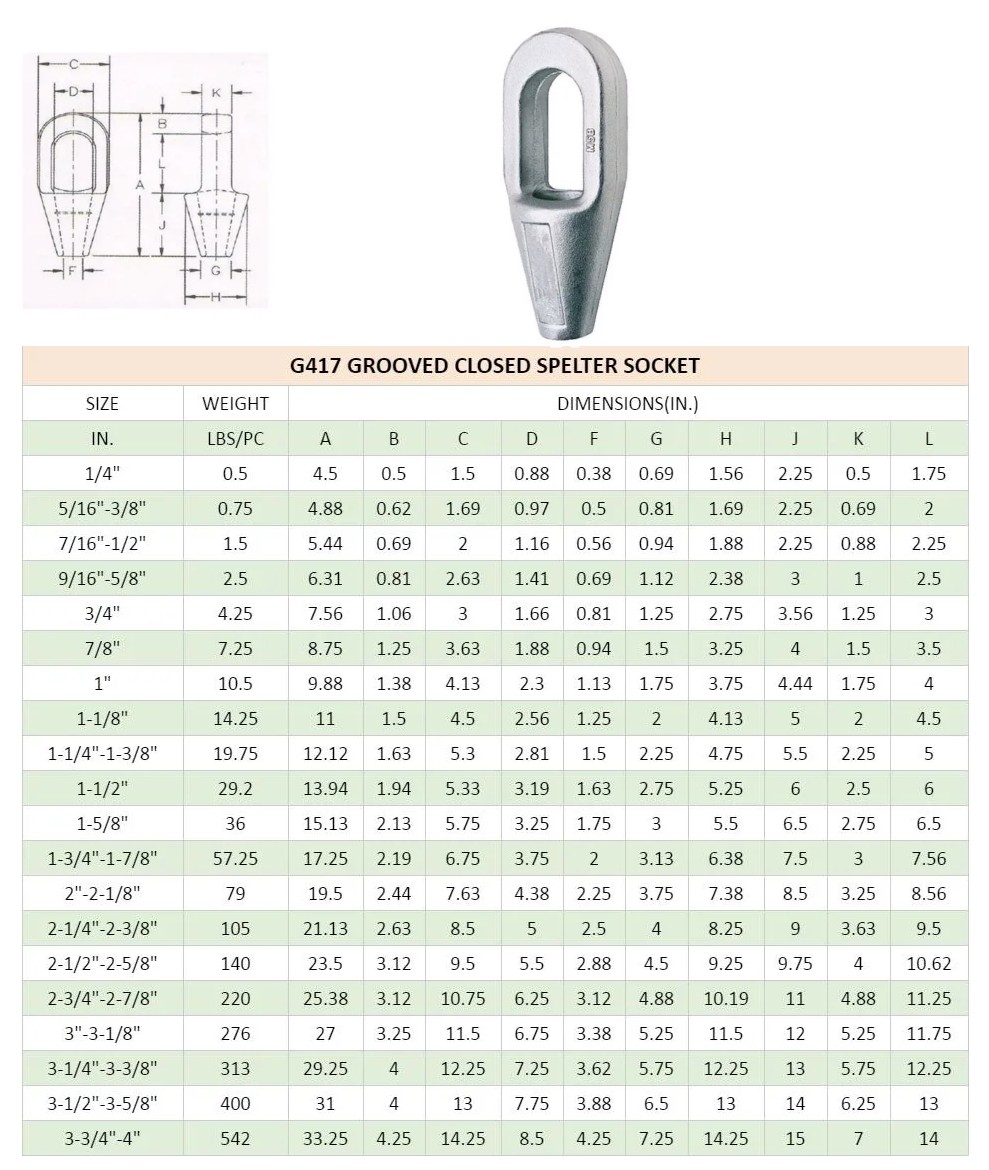

G417 Forged Closed Spelter Socket for Wire Rope Sling

The G417 Closed Spelter Socket is a specialized end-fitting hardware used in the termination of wire ropes. Commonly employed in heavy lifting, marine, construction, and industrial applications, this type of socket is valued for its strength, reliability, and long-term performance under demanding conditions.

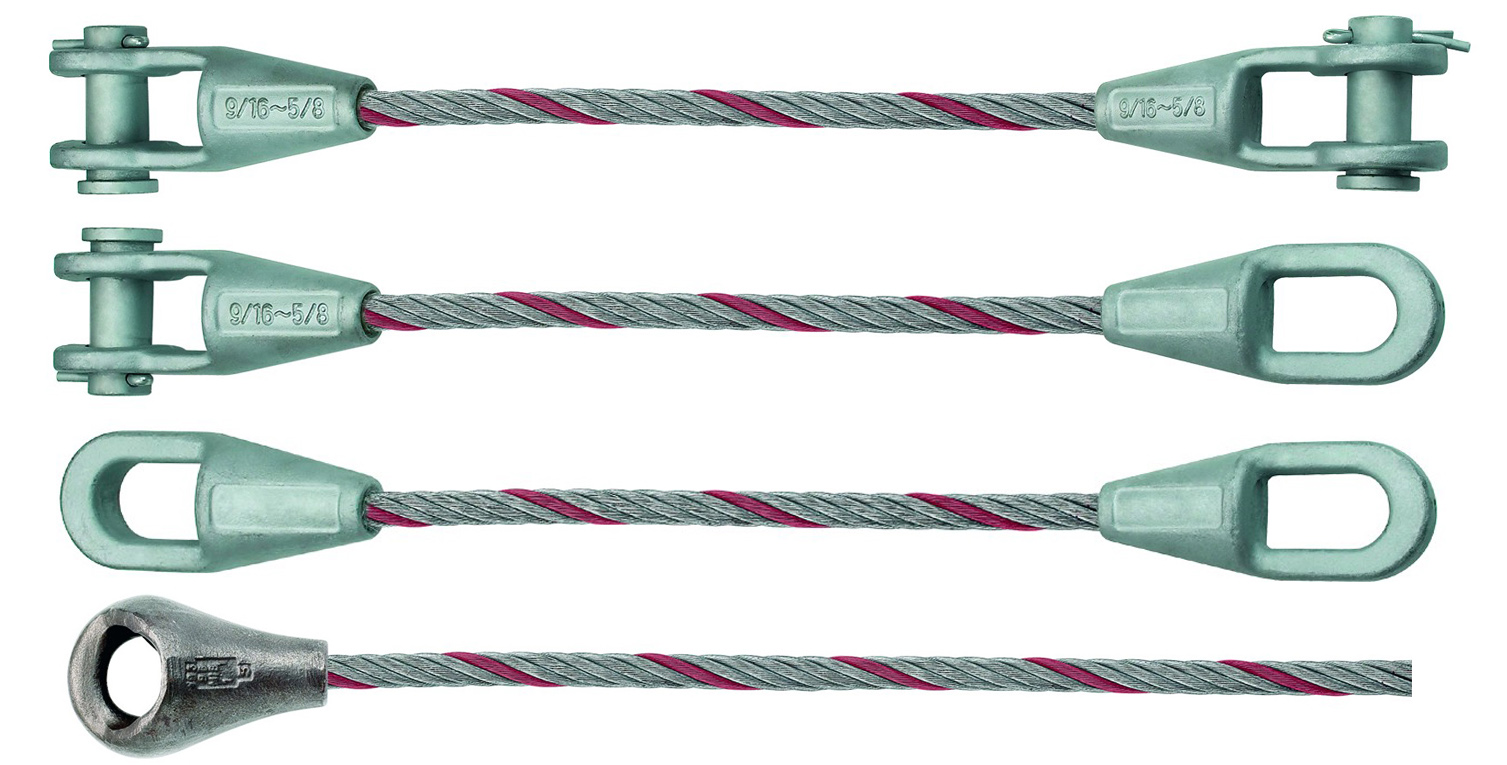

A spelter socket is a type of mechanical end fitting used to create a secure termination on a wire rope. The “closed” variant, such as the G417, features an enclosed eye rather than an open clevis or forked end. This design is intended for use where a pin or shackle will be used to connect the socket to other hardware.

The G417 is a closed spelter socket specifically designed to be permanently affixed to wire ropes using either molten zinc spelter compound or resin-based compound, depending on application requirements and safety standards.

Design and Construction

The G417 Closed Spelter Socket typically features:

- High-strength forged steel or cast steel body for durability and load-bearing capacity.

- Galvanized finish or corrosion-resistant coatings to withstand harsh environments, particularly in marine or offshore applications.

- A closed eye loop that enables secure connection to shackles, hooks, or pins.

- Tapered internal cavity designed to hold molten zinc or resin that encapsulates the wire rope strands for a secure bond.

This design ensures the full strength of the wire rope is retained in the termination, making the socket ideal for critical load-bearing applications.

Benefits of Using G417 Closed Spelter Socket

- High strength termination that matches or exceeds the breaking strength of the wire rope.

- Long-term durability in extreme environments, especially with corrosion-resistant materials.

- Secure and permanent connection that minimizes slippage or deformation under load.

- Versatility across multiple industries and project types.

Model Number: G417 Closed Spelter Socket

-

Cautions:

Proper installation of a G417 Closed Spelter Socket is essential for safe and effective use:

-

Prepare the Wire Rope: Unlay the strands at the end of the rope to expose the core and ensure proper bonding.

-

Position the Socket: Insert the prepared rope into the socket’s tapered cavity.

-

Pouring the Compound:

-

Spelter (Zinc): Molten zinc is poured into the socket cavity to encase the wire strands.

-

Resin System: A two-part resin compound is mixed and poured in, offering a lower-heat alternative with strong bonding capabilities.

-

-

Curing and Inspection: The assembly is allowed to cure and then inspected for correct filling and bonding.